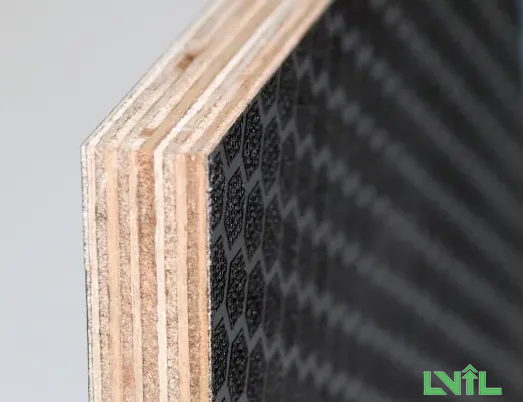

Film-faced plywood is a strong exterior plywood used in building and construction projects. Its surface has a film coating which gives the plywood a higher resistance to moisture, abrasion, and fungal attacks compared to ordinary plywood. With the above advantages, what is film-faced plywood use? Vietimber

Vietimber

Vietimber

Film-faced plywood uses for making formwork in construction because of its increased stability and resistance to moisture, ultraviolet radiation, and corrosive chemicals. The film layer and acrylic varnished edges make it more durable and less able to distort when used outdoors in harsh weather and adverse conditions. Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

Film-faced plywood is highly recommended for shuttering boxes used to contain and mold wet concrete during the drying process. Its durable construction ensures longevity, even under direct sunlight, allowing for multiple uses before replacement. This not only saves costs but also enhances safety and efficiency in construction projects.

Film-faced plywood shares similarities with marine plywood, utilizing high-quality hardwood and waterproof glue to offer a lightweight, sturdy, and virtually defect-free material. Known as "Water-boiled Plywood," it can withstand boiling in water for extended periods—20 to 60 hours—without delamination. These attributes make film-faced plywood a preferred choice in boat and shipbuilding industries for constructing vessels and their components.

In dam construction and maintenance, film-faced plywood is used to fabricate formwork for molding boards and girder molds. These boards withstand exposure to fast-flowing water due to their exceptional water resistance. Available in various thicknesses—such as 12mm, 15mm, 18mm, 21mm, 24mm, and 27mm—film-faced plywood meets diverse industrial needs effectively. Vietimber

Film-faced plywood is widely employed in furniture making due to its superior technical properties, making it highly favored in the industry. It effectively mitigates issues like warping and is resistant to termites, offering a variety of styles and wood grains to suit different applications.

Moreover, the outer film layer enhances the natural appearance of the plywood, providing a range of colors and textures—from vibrant hues to rich, luxurious shades—to cater to diverse aesthetic preferences. The film veneer not only enhances the visual appeal but also protects the furniture's color over time. RAINFOREST WOOD CO.,LTD

Natural wood is a traditional formwork material known for its low cost and ease of production. Its primary advantage is affordability. However, constructing and dismantling wooden formwork can be time-consuming. Additionally, natural wood is susceptible to warping under harsh weather conditions and adverse environments. Vietimber

Steel formwork is increasingly popular due to its long lifespan and reusability. Although initially expensive, steel formwork can be used across numerous projects, making it cost-effective in the long run. It provides a smooth finish to concrete surfaces and is ideal for circular or curved structures such as tanks, columns, chimneys, drains, tunnels, and retaining walls.

Plastic formwork is a lightweight, interlocking modular system that can be reused over 100 times. It is suitable for simple concrete structures and is becoming popular for projects with similar shapes and large-scale housing developments. The ease of use and durability make plastic formwork an attractive alternative. https://www.vietimber.com