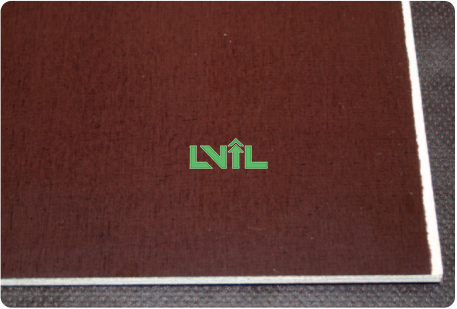

Film-faced Plywood is the special plywood with one or two sides coated with wearable and water-proof film which protect the core from moisture, water, weather and extend the plywood’s life. The application of film-faced plywood is for shuttering plywood, formwork plywood, concrete formwork, floorboard, vehicle building.

Vietimber

Film-faced plywood is the most popular plywood produced by manufacturers in Vietnam. There are 5 common defects of film faced plywood by Vietnam manufacturers: Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

https://www.vietimber.com

Burn film is the most popular defect of film-faced plywood. Burn film is the film integrity damage caused by internal or external defects.

RAINFOREST WOOD CO.,LTD

Reason:

www.vietimber.com

Local bubbles on the plywood surface are caused by glue line delamination, which appears local bulges on the plywood surface.

https://www.vietimber.com

Reason:

Lamination is the splitting of two adjacent veneer layers along with the glue layer. And this makes the plywood weak and it’s not acceptable for a finished plywood. www.vietimber.com

Powered by Vietimber

Powered by Vietimber

Reason: RAINFOREST WOOD CO.,LTD

https://www.vietimber.com

Film powdering is the breaking of the laminating film away from the underlying plywood base along the edges. It’s caused by the worker’s mistake when put the film into the face before the hot-press process. Powered by Vietimber

www.vietimber.com

www.vietimber.com

The above is the most popular defects of Film faced Plywood in many Vietnam manufacturers. There are many solutions which manufacturers should apply to decrease the defective rate such as:

RAINFOREST WOOD CO.,LTD

(1) The moisture content of veneer should be controlled strictly before and during production.

RAINFOREST WOOD CO.,LTD

(2) Control glue spread according to production technology. https://www.vietimber.com

(3) Reduce pressure on hot-press and cold-press in low speed.

(4) The quality of resin should be checked carefully. https://www.vietimber.com

(5) Prevent displacement of veneer.

(6) Pay attention to control aging time. Powered by Vietimber

(7) Control quality of glue liquor. Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

(8) Improve the workmanship in hot-press.

Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

RAINFOREST WOOD CO.,LTD

However, these pre-finished solution does not completely prevent the plywood from the defect as many parts of the manufacturing process is participated by humans. To ensure quality, after manufacturing inspection is utterly important. With many years of manufacturing experience and a deep understanding of plywood, Vietimber Group ensures not only input, manufacturing process but also the finished goods. We establish a professional Quality Control Team to inspect meticulously every piece of Plywood, do the testing and make a report for all consignments before on board. RAINFOREST WOOD CO.,LTD