To many veneer producers, the whole drying phase is a bit unclear as it is comprehensive. Drying is one of the key elements in veneer production and mastering it takes your whole production to the next modern and high-quality level.

The two most important take-aways of this article are the outcomes of successful veneer drying: savings in production costs and the meaning of drying.

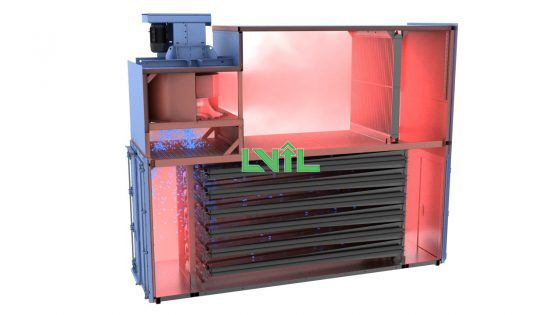

Veneer drying constitutes the critical process of moisture extraction from freshly sliced veneer sheets through controlled application of heated air within specialized drying chambers. This technical procedure reduces veneer moisture content to optimal levels (typically 8-14%) essential for successful adhesive bonding and subsequent hot pressing in plywood/LVL manufacturing 1. As industry standards dictate, maintaining precise moisture equilibrium prevents critical defects including:

Modern drying optimization focuses on achieving "controlled residual moisture" - maintaining just sufficient dampness (≤14% MC) to facilitate glue penetration while minimizing energy consumption. Key implementation strategies include:

Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

The operational benefits of optimized drying regimes manifest immediately through:

✓ 25-30% reduction in raw material waste

✓ 18-22% energy savings via continuous operation cycles

✓ 99.5% planarity retention through controlled S-shaped web transport 2

Advanced drying systems like MINGHUNG's multi-layer mesh dryers demonstrate industry-leading performance, combining: Powered by Vietimber

Technical Specifications Comparison Vietimber

| Parameter | Conventional Dryers | Optimized Systems |

|---|---|---|

| Energy Efficiency | 45-55% | 70-75% |

| Drying Rate | 1.2-1.5 m/min | 2.0-2.5 m/min |

| Defect Rate | 4.5-6.0% | ≤1.0% |

| Maintenance Intervals | 300-400 hrs | 800-1,000 hrs |

This evolution from basic drying to precision engineering transforms veneer processing into a lean manufacturing operation, directly contributing to 15-20% overall production cost reduction in plywood plants 1. www.vietimber.com

Vietimber

Vietimber

The successful veneer drying has many positive impacts on your production and veneer quality. With optimized veneer drying conditions, equipment, and process, you produce more high-quality veneer with less energy consumption and raw material usage and waste.

Before drying veneer sheets, they need to be sorted and stacked by their natural moisture content. Usually, the initial moisture content of veneers varies considerably. That is why before drying the veneer sheets, they need to be sorted and stacked in the peeling line by their natural, initial moisture content. So, to optimize the drying result, by sorting and stacking the sheets by moisture content you get smaller deviation and thereby a better outcome. Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

By only stacking the sheets into two different moisture groups you get significant savings and more optimized drying result compared to not dividing the sheets. The savings come from energy consumption in heating and operating the dryer. Increasing the number of the moisture groups, you concurrently increase savings, drying capacity, and the veneer quality.

https://www.vietimber.com

If the sheets are divided into three or more moisture classes, you inevitably increase your savings, drying capacity, and what’s more, the veneer quality. RAINFOREST WOOD CO.,LTD

The short answer is that you are still capable to do the drying, but the production efficiency and the veneer quality decrease. The only way to minimize the deviation of the end-moisture content, in general, is to lower the veneer sheet’s end-moisture content. This leads to over-drying some sheets. RAINFOREST WOOD CO.,LTD

Respectively, if the sheets are sorted, the average moisture content can be increased without having to increase the number of wet sheets. This sorting results in increased veneer sheet quality. With this action, the increased quality is reflected, and the savings and complete quality improvements recur. Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

The sorting needs to be done with analyzers. This is the only way the sorting is accurate. Pressing the sheets can be done for high moisture veneer stacks after the moisture sorting and before drying.

Vietimber

Reduce drying time and cost with wet veneer pressing. Using this technique before the dryer, the veneer sheet’s starting moisture content decreases which means that there is less water inside the sheet that needs to be evaporated. Naturally, this means lower energy consumption. This also levels the moisture content between the sheets which results in a better drying outcome. https://www.vietimber.com

With analyzers. The moisture content is measured with a specified moisture analyzer, and the sheet´s visual quality is measured with a visual analyzer. With this information, the sheets are sorted into the correct categories before drying. In this stage, poor quality sheets can be separated into different stacks to avoid messing up the drying of the good quality sheets.

https://www.vietimber.com

To dry the sheet optimally, you should use an automated veneer sheet dryer. The automated drying process aims to dry the green veneers to a moisture content suitable for gluing. Too high veneer moisture hampers gluing and generates steam during hot pressing. Automatic process control maintains the speed, temperature, and humidity inside the dryer at an optimal level. RAINFOREST WOOD CO.,LTD

Drying is simple and easy when the sheets have been correctly pre-sorted by initial moisture content. The foundation for successful veneer drying is proper pre-sorting of the sheets. This is the step where major savings and improvements can be done. Drying should aim at correct end-moisture content depending on the product and raw material, as discussed before but not too dry (over-drying) as this makes the veneer fragile, wavy and increases glue consumption when making panels.

Vietimber

One also notable thing to look for, is rotten parts in a sheet, as we mentioned before. The rot is seemingly difficult and consuming to dry, so these sheets with rot should be stacked separately from good-quality sheets.

The sheet feeding to the dryer needs to be continuous and therefore you should pay close attention to the stacks that come from the lathe. Also, the operators’ fast reactions when removing possible trash or unwanted particles are crucial at this point to enable the high-quality, continuous process. Overlapping the veneers has been proven to increase the drying capacity to maximize the production. Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

A successful drying outcome is ensured with consistent drying conditions and high humidity inside the dryer. In the long run, you need to be sure that the veneer drying line is maintained correctly and continually, so the conditions stay the same despite other factors. One good way to ensure this is to modernize old machinery to guarantee high-quality production and end-products.

Vietimber

The energy required to dry the veneer can be produced from the mill’s by-products.

As a result, you get high-quality, even moisture content veneer sheets that are ready to be glued and processed further as LVL beams, plywood, panels, or other end- use products.

Powered by Vietimber