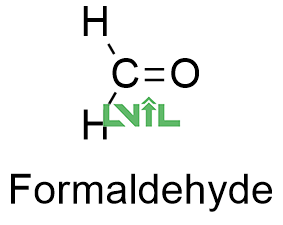

Formaldehyde is used in glue in the manufacture of wood based panels including plywood, particle board and MDF. It is used for the formulation of wood-based panel adhesives and very hard to substitute. Vietimber

Formaldehyde emission is very high in newly manufactured plywood. So it is important to control the quality of glue used for plywood.

Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

Vietimber

Vietimber

American Standard For Formaldehyde Emission in Plywood

Powered by Vietimber

CARB Phase 2 www.vietimber.com

Regulated by California Air Resources Board(CARB) www.vietimber.com

From March 22, 2019, all hardwood plywood sold in United States must be labeled as TSCA Title VI compliant. Plywood sold, supplied, offered for sale, imported to, or manufactured in the United States are in compliance with the emission standards. Powered by Vietimber

Hardwood plywood made with a veneer core or a composite core should meet 0.005ppm in formaldehyde emission testing. www.vietimber.com

See more details: https://www.epa.gov/formaldehyde/formaldehyde-emission-standards-composite-wood-products www.vietimber.com

Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

European Standard (EN 13986:2004) related to factory production control for wood based panels. www.vietimber.com

European Low Emission Standard

(E.LES) sets different emission limits for different product groups.

Under E.LES the

formaldehyde emission limit for fibreboard and OSB is consistent with E1 (= 0.1 ppm or

0.124 mg/m3

) but is set to a lower value of 0.065 ppm (= 0.08 mg/m3

) for particleboard

and plywood. Powered by Vietimber

https://www.vietimber.com

Japanese JAS 4-Star Rating Standard Powered by Vietimber

Chinese Standard Vietimber

The latest formaldehyde standard is China released GB/T 39600-2021 as an update for GB 18580-2017.

https://www.vietimber.com

E0 formaldehyde emission grade was first introduced in this new national standard and E2 grade was abandoned. https://www.vietimber.com

ENF is one of the strictest standards for formaldehyde emission in the world. Powered by Vietimber

Formaldehyde-based adhesives for wood-based panels are UF and MUF resins and to a lower extend PF resins. Formaldehyde-free plywood is made with pMDI. For the next years, conventional adhesives with reduced or no formaldehyde emissions will maintain their dominating position. The importance of alternative resins will increase but on a lower level as often proposed. RAINFOREST WOOD CO.,LTD

Vietimber

Technically there is no formaldehyde-free plywood. However, there are no-added formaldehyde (NAF) and ultra-low emitting formaldehyde-based resins (ULEF) for plywood manufacture. These materials make low emission plywood.

Powered by Vietimber

RAINFOREST WOOD CO.,LTD

Choose E1 or E0 grade plywood for your flooring, cabinets and furniture. Test the plywood if you have doubts about the quality of the material used in your decoration. Vietimber

Powered by Vietimber

Solid timber is better than engineered panels. Timber is extra low in formaldehyde compared with the plywood. Using a lot of E1 grade plywood won’t help with the situation. Too much engineered wood in a room still release a lot of formaldehyde.

Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.

Make the plywood laminated or coated. You may use a vapor barrier such as some paints, varnishes, or a layer of vinyl or polyurethane-like materials. Be sure to seal with a material that does not contain formaldehyde. Copyright © RAINFOREST WOOD CO.,LTD. All Rights Reserved.